- Home

- Raw Material Led Lenses

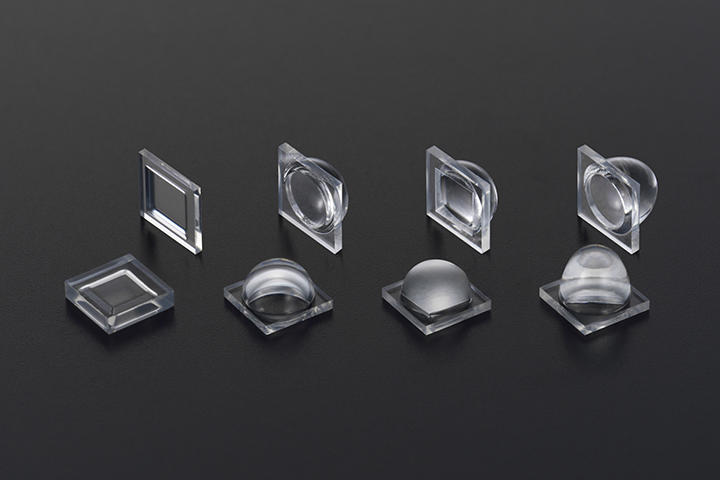

Comprehensive Guide to Used Raw Materials for LED Lenses

LED lenses play an important role in enhancing the performance of LEDs by controlling light distribution, beam angles, and intensity. The choice of raw materials for LED lenses significantly influences their longevity, efficiency, optical clarity, and thermal performance. At Krishani LED Lenses, we aim to use high-quality raw materials to fulfill the rigorous demands of applications, including automotive, industrial, commercial, and architectural lighting. This guide will identify the raw materials most used in LED lenses and their properties, advantages, and applications.

1. Silicone (SIO3) - Silicone (SiO?) is also commonly used for LED lenses because of its superior flexibility, thermal stability, and optical transparency. It can withstand degradation and loss of mechanical properties under tough environmental conditions and is, for this reason, ideal for exterior and industrial applications. The general properties of silicone include:

- Works well between -40°C to 200°C peak without yellowing or cracking.

- Silicone lenses have excellent light transmission and low birefringence

- liIt resists harsh environmental stresses such as UV exposure, micro-cracking, and immersion.

2. PMMA (Acrylic) - Polymethyl methacrylate (PMMA) or acrylic is a clear thermoplastic, economical, and lightweight polymer. It allows as much as 92% of visible light through, making it one of the finest choices for precision-molded lenses that need very high transparency. It is most often utilized in LED lenses due to:

- Carries as much as 92% of light, ideal for use in optical-grade applications.

- Excellent resistance to UV light and aging degradation.

- Tensile strength is 7–18 times higher than regular glass.

3. Polycarbonate (PC) -Polycarbonate is a high-performance thermoplastic with impact resistance and thermal stability. PC is ideally suited for tough environments like sports and stadium, industrial lighting, and transportation applications where mechanical shock or vibration may occur. Its most important characteristics are:

- 7–18 times stronger than glass, ideal for harsh conditions.

- Supports around 90% transmission of visible light, along with the special benefit of dimensional stability.

- It is resistant to temperatures up to 120°C without distortion, which makes it perfect for LED light covers.

4. Epoxy Resin - Epoxy resins are used in LED lenses due to their high adhesive capability, chemical stability, and hardness. Although not as optically clear as PMMA or silicone, epoxy is commonly used for encapsulating lenses and LED chips in low-volume applications. The advantages are:

- Maintains stability in high temperatures without degrading.

- Maximizes optical performance through maximum light extraction and minimum loss.

- Enduring mechanical stress and chemical exposure over extended service life in rugged environments.

5. Liquid Silicone Rubber (LSR) - Liquid silicone rubber (LSR) is ideal for high-volume, high-precision molding, providing shock and heat resistance as well as reliable optical quality. Compared to rigid thermoplastics, LSR can be cast into complex shapes while ensuring good light transmission. We employ LSR in waterproof-sealed LED modules, such as in underwater lighting, road lighting, and medical LED devices. The key advantages are:

- Resists deforming when stressed.

- Works well under extreme conditions.

- Aids in equal shrinkage and optical uniformity

6. Thermoplastics - Thermoplastics like PMMA, PC, and COC (Cyclic Olefin Copolymer) are popular materials for LED lenses because they are moldable, are light in weight, are recyclable, and have good optical properties. Thermoplastics are fantastic for quickly creating prototypes and manufacturing optical parts in large quantities. We utilize them to make custom LED lenses that are highly consistent. Here's the gist of why they're great:

- Molded into really complex optical shapes.

- Affordable compared to glass optics.

- Comes in different grades to match specific optical needs.

7. Boron Oxide - Boron oxide is an important component in glass lenses used in high-precision optical applications. It provides thermal resistance and mechanical toughness, making it ideal for unique LED optics. It is used in precision glass lenses and temperature-resistant LED devices, such as laboratory or industrial lighting equipment.

- Enhanced mechanical strength for robust lenses

- Excellent optical performance, such as low light absorption.

- Remains stable at high temperatures and resists environmental wear and tear.

8. Gallium Arsenide (GaAs) - Gallium arsenide (GaAs) is not a lens material, but it is a semiconductor that plays a vital role in making infrared LEDs and laser diodes. Its distinctive electrical and optical properties make it suitable for high-efficiency emission of non-visible wavelengths. However, we use lenses particularly designed for GaAs-based LEDs. The key properties are:

- High electron mobility for optimal LED performance

- High thermal conductivity for heat dissipation

- Applied in high-brightness LEDs for increased luminosity

9. Gallium Phosphide (GaP) - Gallium phosphide (GaP) is a second semiconductor material used in LEDs, particularly for yellow and green light emission. In combination with other compounds, it allows light color optimization and tuning. GaP materials find application in signal illumination, indicator LEDs, and color-specified illumination arrays requiring efficient and stable emission of colors. The advantages are:

- Good thermal and electrical conductivity.

- Material that lasts long for stable LED operation.

- Excellent efficiency in coloured LED light emission.

Material Selection Guide for LED Lenses

.png)

Why Choose Krishani LED Lenses?

At Krishani LED Lenses, we are driven by core values that guide our business and define our commitment to our clients.

Expertise and Experience - With years of experience in the optical and lighting industries, we have the expertise to deliver custom-designed solutions that meet the most demanding requirements.

High-Quality Products - Our lenses are made from high-quality materials, ensuring durability, clarity, and long-lasting performance.

Custom Solutions - We specialize in providing tailored LED lens solutions that meet the unique needs of our clients.

Exceptional Customer Service - We provide end-to-end support, from initial consultation to post-delivery assistance, ensuring our clients are delighted with the results.

Your Trusted Partner in Advanced LED Lens Materials

Selecting the appropriate material is crucial to the performance of LED lenses. At Krishani LED Lenses, we use superior-quality materials such as silicone, PMMA, PC, epoxy resin, and LSR with advanced manufacturing processes to provide high-quality optical solutions. These materials possess specific properties that enhance the performance of LEDs. We provide custom LED lens solutions to your project requirements, so contact us today at +1 917-730-4350 or info@krishaniledlenses.com.

Ready to See your Idea into Reality

We have served 157+ Clients so far… Discuss your Requirements with Our Experts.